If it is an indispensable part to make rubber raw rubber into a variety of mature rubber products, what are the links of rubber mixing? The following is a professional rubber manufacturer to introduce you to the four major steps of rubber mixing.

First, the choice of mixing materials, in the process of mixing, due to the low cohesion between the rubber molecules, the high-strength and high-temperature silica filler becomes the most important compounding agent for rubber. When other compounding agents are used, Need to consider the requirements of high temperature resistance, that is, under the application conditions of rubber, they should not be volatilized, decomposed, charred or discolored, etc. In order to maintain the heat resistance of raw rubber, the silicon bond is reduced by acid and alkali, and the mixture is broken and mixed. To prevent the introduction of foreign acids and alkalis, it is necessary to remove the acidic substances generated by the decomposition of the peroxide vulcanizing agent in time.

Second, in the mixing of the raw rubber and other ingredients into the vacuum kneader, the temperature is not high at the beginning, during the stirring process, by the temperature of the temperature slowly reached 155-160 degrees, It will take another half hour.

Third, put the cooked glue in the open mill to smooth and roll into a roll. Just take care not to get dirty. The number of rolls only needs 2-3 rings.

Fourth, after smoothing, it should be cooled. The time is about 3-4 hours. Then, through the match net, the glue is filtered again. The purpose is to filter out some solid materials inside the glue.

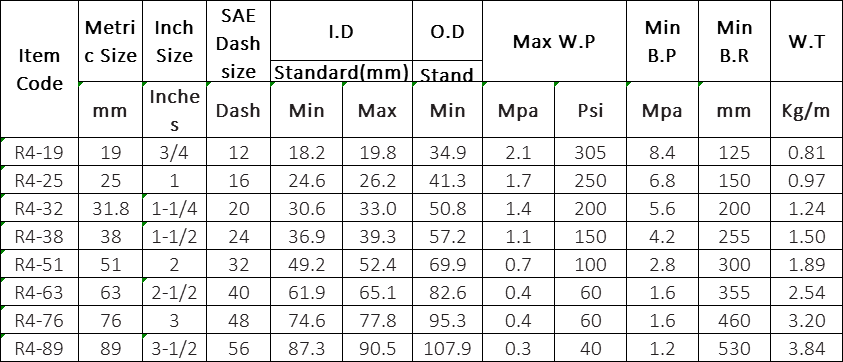

SAE 100 R9 steel wire spiraled hydraulic hose is suitable for delivering petroleum-based hydraulic oils in the working temperature of -40 °C to +100 °C.

Recommended For: Extremely high pressure, high impulse hydraulic applications. Exceeds all performance requirements for SAE 100 R9 / R10 / R12, EN856 R9 / R10 / R12, SAE 100 R12 and EN856 4SP. Compatible with biodegradable hydraulic fluids like synthetic esters, polyglycols and vegetable oils as well as petroleum-based fluids.

Tube: Black, oil-resident synthetic rubber (Nitrile)

Reinforcement: Four alternating layers of spiraled, high-tensile steel wire.

Cover: Black, oil-resistant synthetic(Nitrile).

Tube: Black, oil-resident synthetic rubber (Nitrile)

Reinforcement: Four alternating layers of spiraled, high-tensile steel wire.

Cover: Black, oil-resistant synthetic(Nitrile).

Temperature Range: -40℉ to +250℉ (-40℃ to +121℃)

Application: Hydraulic system service with petroleum and water-based fluids, for general industrial use.

Products Application:

Hydraulic rubber hose SAE100 R9 SAE100 R10 SAE100 R12 can be used for forklift,hydraulic engine,oilfield extraction machinery, mine / road / construction machinery and so on.

Application: Hydraulic system service with petroleum and water-based fluids, for general industrial use.

Products Application:

Hydraulic rubber hose SAE100 R9 SAE100 R10 SAE100 R12 can be used for forklift,hydraulic engine,oilfield extraction machinery, mine / road / construction machinery and so on.

(4) Light: The shorter the light wave, the greater the energy. What is damaging to rubber is the higher energy of ultraviolet light. In addition to ultraviolet rays directly causing the breakage and cross-linking of rubber molecular chains, rubber generates free radicals by absorbing light energy, which initiates and accelerates the oxidation chain reaction process. Ultraviolet light plays a role in heating. Another feature of light action (unlike heat) is that it mainly occurs on the surface of the oak. For samples with high gel content, there will be reticular cracks on both sides, the so-called “outer layer cracking”.

(4) Light: The shorter the light wave, the greater the energy. What is damaging to rubber is the higher energy of ultraviolet light. In addition to ultraviolet rays directly causing the breakage and cross-linking of rubber molecular chains, rubber generates free radicals by absorbing light energy, which initiates and accelerates the oxidation chain reaction process. Ultraviolet light plays a role in heating. Another feature of light action (unlike heat) is that it mainly occurs on the surface of the oak. For samples with high gel content, there will be reticular cracks on both sides, the so-called “outer layer cracking”.